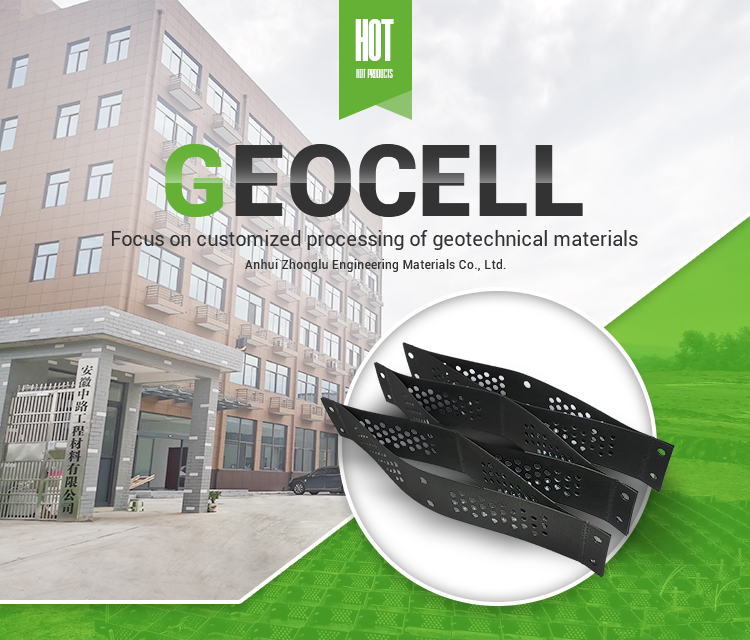

Factory Smooth Textured Perforated Gravel Grid Plastic HDPE Geocell Price For Soil Reinforcement Anti-Corrosion For Road

- Type:Geocells

- Warranty:5 years, More than 5 years

- After-sale Service:Online technical support, Onsite Installation, Onsite Training

- Project Solution Capability:graphic design, 3D model design, total solution for projects

- Application:Earthwork Apllication, Building, Road Basement

Description:

-

Type

Geocells

Warranty

5 years, More than 5 years

After-sale Service

Online technical support, Onsite Installation, Onsite Training

ProjectSolution Capability

graphic design, 3D model design, total solution for projects

Application

Earthwork Apllication, Building, Road Basement

Design Style

Modern

Place of Origin

Anhui, China

Brand Name

zhongloo

Model Number

ZL-TGGS

Product name

HDPE Geocell

Material

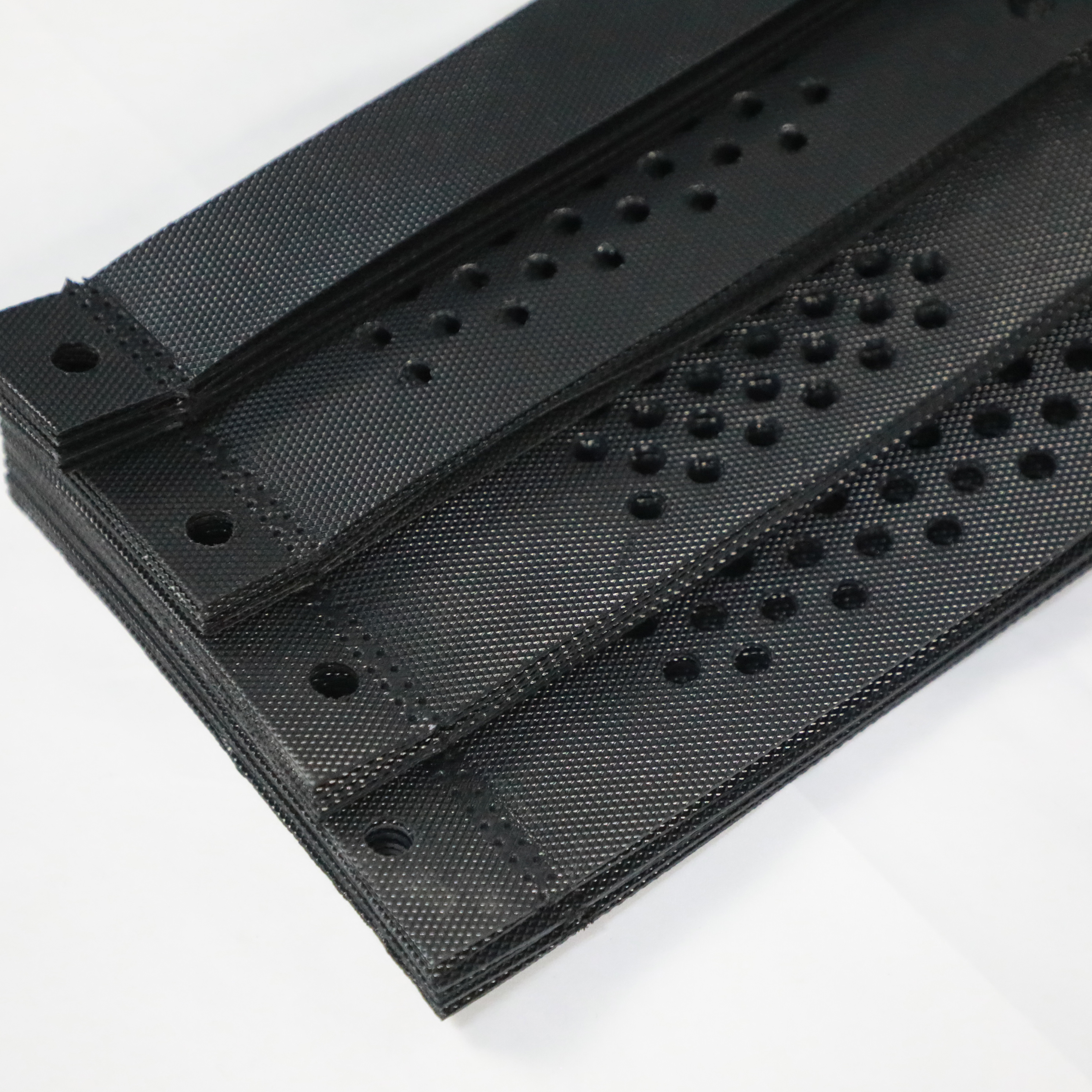

HDPE PP

Color

Black/Yellow/Green/White

THICKNESS

1.0-1.7mm

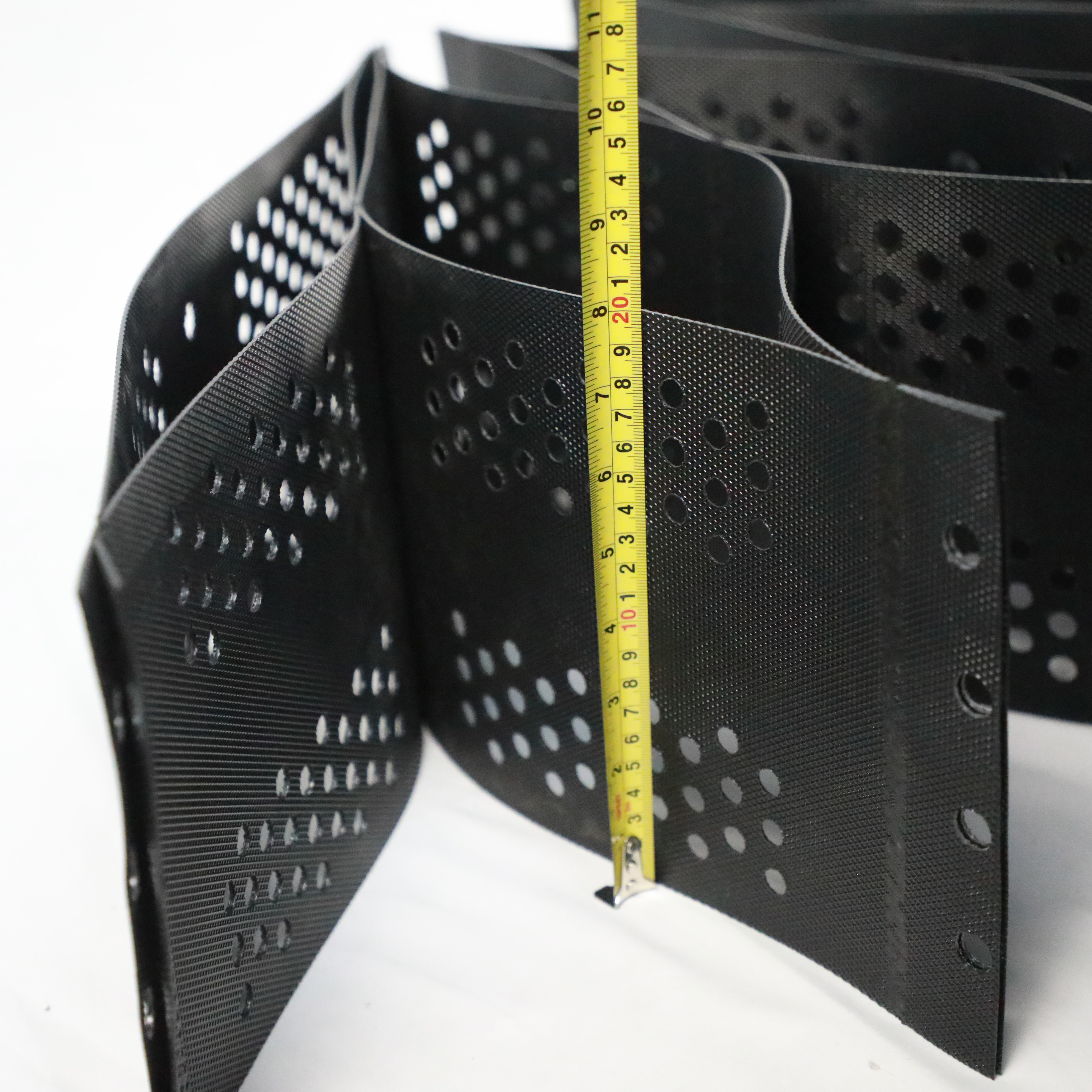

Height

50mm~250mm

Keyword

Soil Stabilization Geocell Grid

Surface

Textured Smooth

WELDING DISTANCE

330mm-1000mm

Supply Ability

60000 Square Meter/Square Meters per DayPackaging & DeliveryPackaging Details

Geosynthetic Material Smooth and Textured Plastic HDPE Geocells System Slope ProtectionGeocell Cellular Erosion Control:Sandard packing or according to customers' or contract requestPort

qingdao port ; shanghai port; ningbo port or According to customers' requirments- Picture Example:

-

- Lead Time:

-

Quantity(square meters) 1 - 10000 10001 - 30000 >30000 Est. Time(days) 8 12 To be negotiated

Online Customization

Click the image below to start online customization for the design you want.

Factory Smooth Textured Perforated Gravel Grid Plastic HDPE Geocell Price for Soil Reinforcement Anti-Corrosion for Road

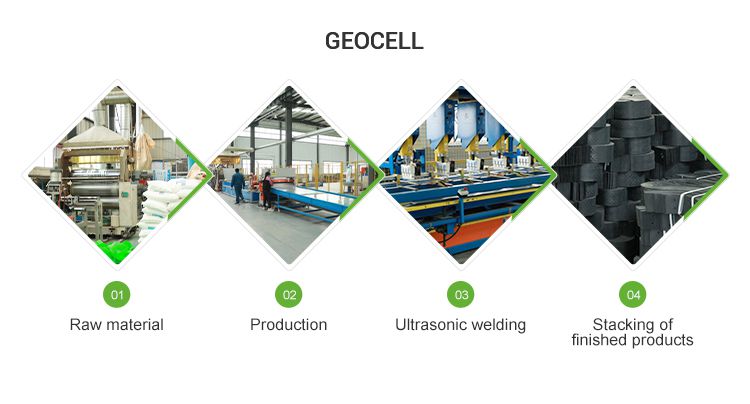

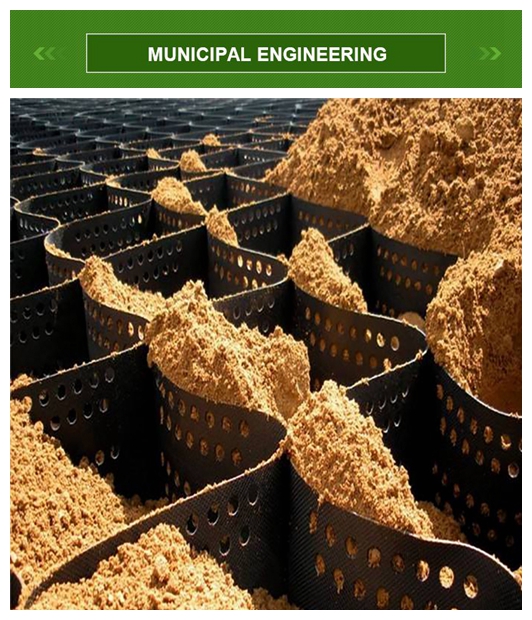

1. It is flexible, foldable for transportation, and stretched into a net during construction. 2. Light material, abrasion resistance, stable chemical properties, photooxidation resistance, acid and alkali resistance. 3. High lateral restriction and anti-skid, anti-deformation, enhance the bearing capacity of the roadbed and disperse the load. 4. Flexible expansion, small transportation volume, convenient connection and fast construction speed.

5. Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

Geocell is reinforced by high intensity HDPE broadband, after the powerful welding face to become a reticular lattice room structure. It retractile,transportation can shrink fold super to,when using ,open and filling earth-rock,or concrete materials,constitute has strong lateral restrictions and taking degrees structures ,it can be used as a cushion,dealing with weak foundation bearing capacity , also can be laid on slope surface slope protection structure constitute, still can be used to build retaining structures,etc

|

Geocell

|

||||

|

item

|

PP

|

PE

|

||

|

tensile strength of Strip ≥(Mpa)

|

23

|

20

|

||

|

Tensile strength of weld ≥(N/cm)

|

100

|

100

|

||

|

Tensile strength of cell edge ≥(N/cm)

|

200

|

200

|

||

|

Intermediate tensile strength of cell sheet ≥(N/cm)

|

120

|

120

|

||

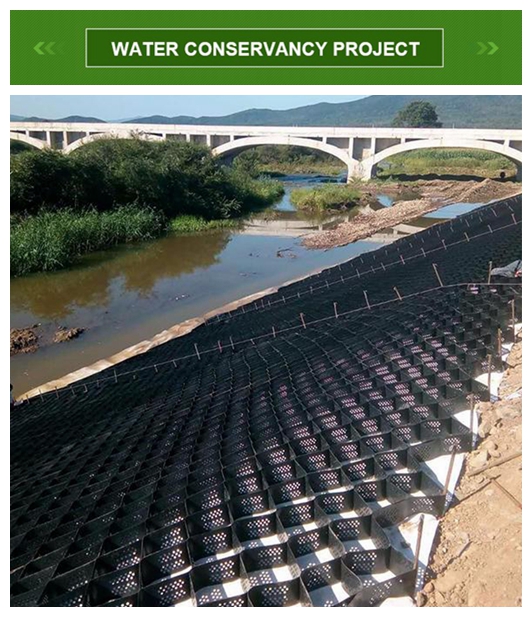

Why Geocell In roads , railways , sewers and slope applications , etc . during construction , sometimes we encountersoft and / or weak soils . The traditional way is to fill with expensive materials , which could be costlyand time consuming . However , there is an effective alternative method , by using geocell directly on the subgrade .geocell is made of ultrasonically-welded high density polythelene ( HDPE ) and can beexpanded to form honeycomb structure . Cells are then filled with readily available granular materialsand compacte.The Geocell solution means to challenge soil stability problems in lots of applications therougn the high-strength network of interconnected cells .

How Geocell Works when infilled with compacted materials , it creates a newcomposite entity that possesses enhanced mechanical andgeotechnical properties When the soil contained within a Geocell is subjected to pressure , it causes lateral stresses on perimeter cell walls.

The 3D zone of confinement reduces the lateral movement of soil particles while vertical loading on the contained infill results in high lateral stress and resistance on the cell-soil interface . These increase the shear strength of the confined soil . which : Creates a stiff mattress or slab to distribute the load over a wider area. Preduces punching of sofl soil. Incrcascs shear resistance and bcaring capacity decreases deformation Confinement from adjacent cells provides additional resistance against the loaded cell through passiveresistance , while lateral expansion of the infill is restricted by high hoop strength . Compaction ismaintained by Geocell resulting in long term reinforcement

Retaining Wall

Cellular Confinement Systems provide steep vertical mechanically stabilized earth structures (either gravity or reinforced walls)

for steep faces, walls and irregular topography

for steep faces, walls and irregular topography

Slope Pretection

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

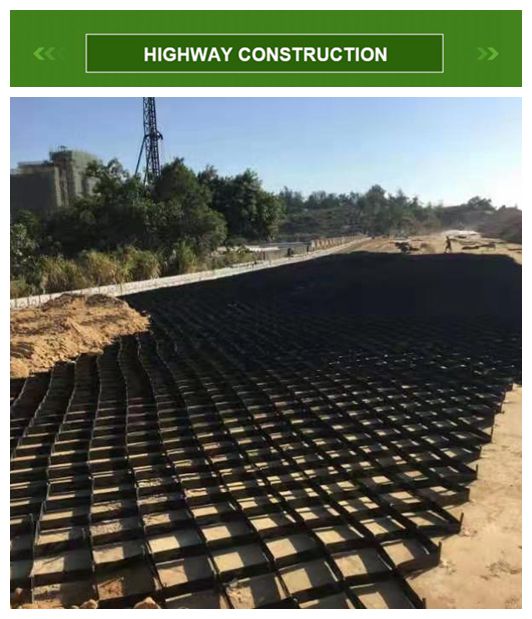

Gruound Stabilisation

Cellular Confinement Systems strengthen the aggregate infill, thereby simultaneously enabling the use of poorly graded inferior material for infill as well as reducing the structural support layer thickness.Typical stabilisation applications include reinforcement of base and subbase layers in flexible pavements, including: roads, railway substructure and ballast confinement;working platforms in intermodal ports; airport runways.

Load Support

Cellular Confinement Systems have been used to improve the performance of both paved and unpaved roads by reinforcing the soil in the subgrade-base interface or within the base course. The effective load distribution of geocell creates a strong,stiff 3D cellular mattress which can reduce vertical differential settlement into soft subgrades, improves shear strength, and enhances load-bearing capacity, while reducing the amount of aggregate material required to extend the service life of roads.