High Strength PP Geotube Sludge Dewatering Dewatering Sediment Bag

1. Professional manufacture.

2. Implement strict quality test & control procedure.

3. High quality & Best price.

4. Products could be customerized.

5. Good after-sale service.

6. Fast delivery time.

Description:

PP High-Strength Geotextile Sand Bag Filter Geotube

Product Description

High efficiency

Can completely satisfy the amount of waste water and sludge processing, processing according to the flow of the pump to increase the number of deductions just leave bags.

| Item | Unit | Testing Standard | Technical Parameters | ||

| GT70X95B | GT70X95 | ||||

| Breaking strength | MD | KN/m | ISO 10319-2015 | 85 | 85 |

| CD | KN/m | ISO 10319-2015 | 105 | 115 | |

| Elongation of break | MD | % | ISO 10319-2015 | 13 | 13 |

| CD | % | ISO 10319-2015 | 8 | 8 | |

| Sewing Tensile Strength | KN/m | ISO 10321-2008 | 70 | 90 | |

| Static Bursting Strength(CBR) | KN | GB/T 14800-2010 | 8 | 9 | |

| Equivalent hole size(O90) | mm | GB/T 14799-2005 | 0.5 | 0.45 | |

| Permeability(Q50) | L/m2/s | GB/T 15789-2005 | 50 | 35 | |

| UV-resistance (500 Hours strength retention) | % | ASTMD4355-2014 | 90 | 90 | |

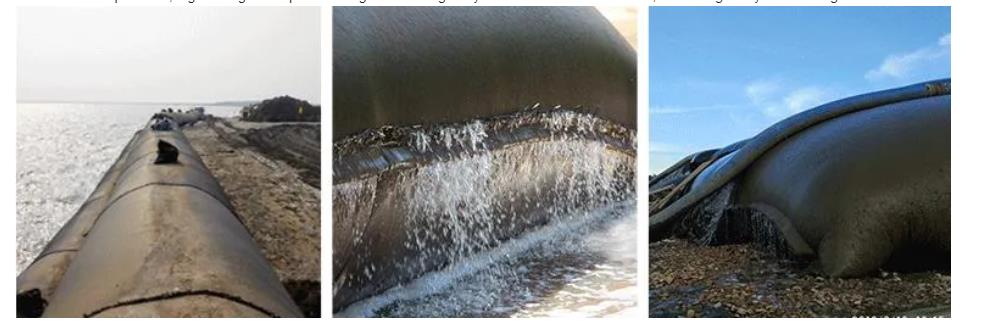

PS: The first step is to fill, high strength and permeable geotextile bag body needed to make into actual, then filling slurry into the bag.

PS: The second step is drainage, because the geotextile that makes up the bag has tiny holes that trap it in the mud, solids can also discharge water from the mud, which can effectively reduce the volume of inclusion in the bag body,The bag body can be repeatedly filled until the allowable height of the bag material is reached, and the discharged water can be reused.

PS: The third step is consolidation. After repeated filling and drainage, the fine particles left in the bag body will gradually consolidate due to drying.

Professional geosynthetics manufacturer

Anhui Zhonglu Engineering Materials Co., Ltd

Summer :86-18056028960