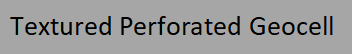

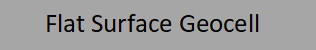

Textured And Perforated HDPE Plastic Geocell Manufacturer Price Gravel Grid Geo Cell Gravel Stabilizer

- Type:

-

Geocells

- Warranty:

-

5 years, More than 5 years

- After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training

- Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

Description:

Quick Details

- Type:

-

Geocells

- Warranty:

-

5 years, More than 5 years

- After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training

- Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

- Application:

-

Earthwork Apllication, Building, Road Basement

- Design Style:

-

Modern

- Place of Origin:

-

Anhui, China

- Brand Name:

-

zhongloo

- Model Number:

-

ZL-TGGS

- Product name:

-

geocell Geo cell enhancement cellular system gravel grid driveway

- Material:

-

HDPE PP

- Color:

-

Black/Yellow/Green/White

- THICKNESS:

-

1.0-1.7mm

- Height:

-

50mm~250mm

- Keyword:

-

Soil Stabilization Geocell Grid

- Surface:

-

Textured Smooth

- WELDING DISTANCE:

-

330mm-1000mm

Supply Ability

- Supply Ability

- 60000 Square Meter/Square Meters per Day

Packaging & Delivery

- Packaging Details Factory low price driveway road slope protection HDPE paving plastic gravel stabilizer geocell manufacturer for sale

- Plastic woven bags for plastic HDPE geocell or according to customer's requirements

- Port qingdao port ; shanghai port; ningbo port or According to customers' requirments

- Picture Example:

-

- Lead Time:

-

Quantity(square meters) 1 - 1 2 - 1000 1001 - 10000 >10000 Est. Time(days) 7 9 11 To be negotiated

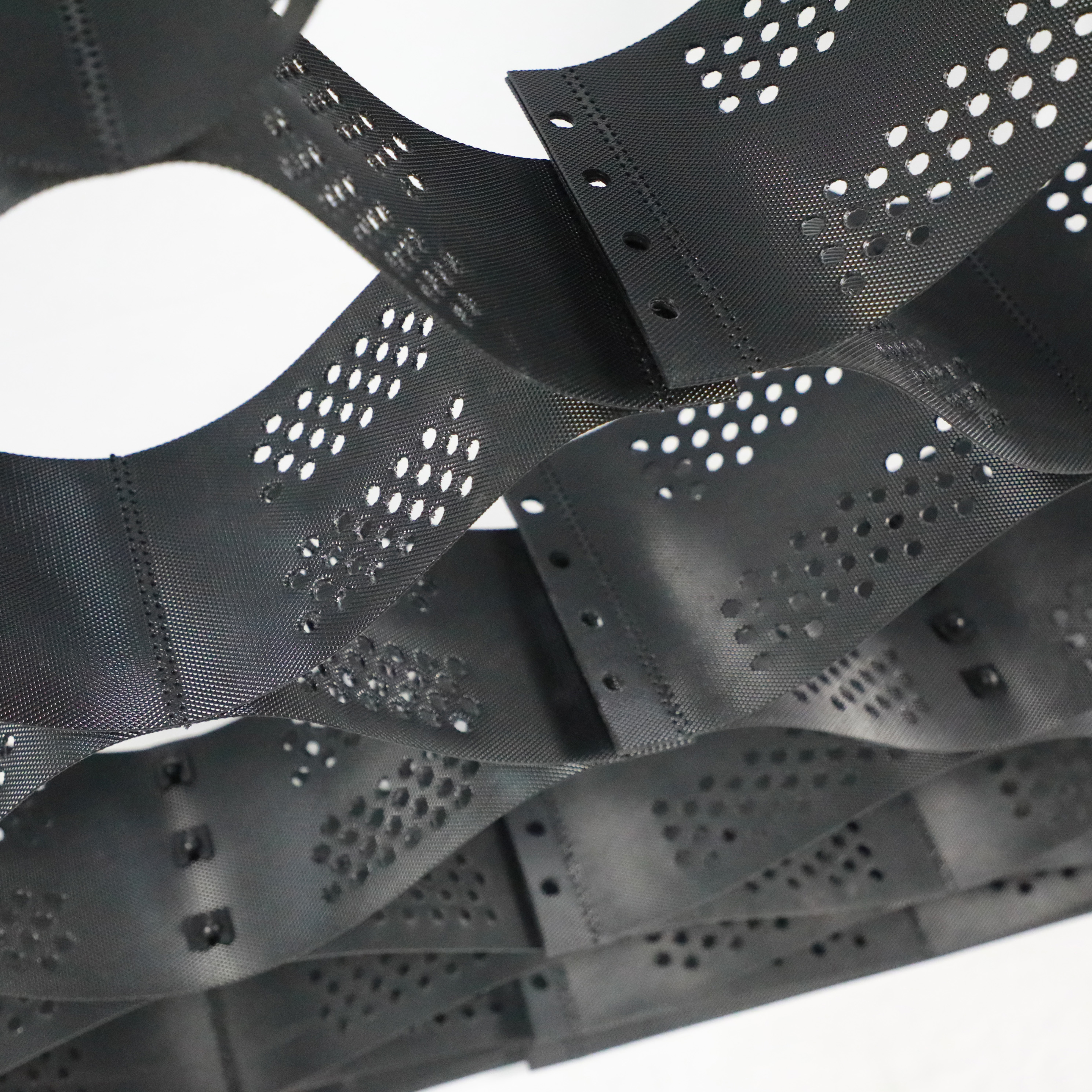

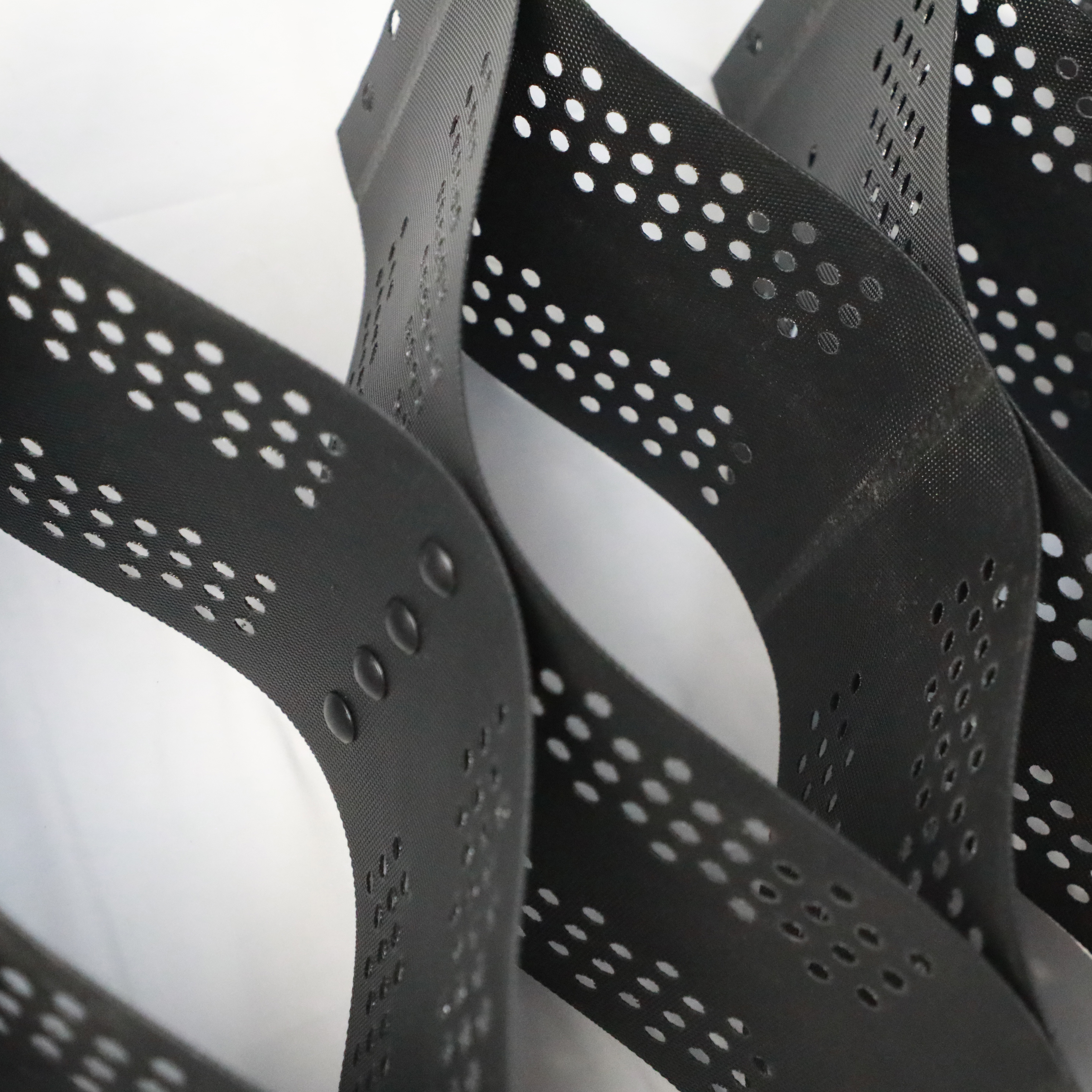

Textured and Perforated HDPE Plastic Geocell manufacturer price gravel grid geo cell gravel stabilizer

Free samples are available.

Products Description

HDPE paving plastic gravel stabilizer geocell basic details:

|

Cell depth

|

50mm ,100mm , 150mm , 200mm , 250mm

|

|

Welding space

|

330mm ~ 1600mm

|

|

Thickness

|

1)1.0mm~1.2mm for smooth geocell

(2) 1.5mm~1.7mm for textured geocell |

1.HDPE Paving Plastic Gravel Stabilizer Geocell Introduction:

Plastic geocell cellular confinement system is three dimensional , honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique . It is flexible to fold during the transport and installation on construction site .The geocell nets will be filled with soils , granular, cements or other on-site infill materials when stretched into web structures , which has powerful and rigid confinement in the lateral and vertical sides .

Plastic geocell cellular confinement system is three dimensional , honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique . It is flexible to fold during the transport and installation on construction site .The geocell nets will be filled with soils , granular, cements or other on-site infill materials when stretched into web structures , which has powerful and rigid confinement in the lateral and vertical sides .

2.HDPE Paving Plastic Gravel Stabilizer Geocell Specifications:

1.Cell depth: 50mm , 100mm , 150mm , 200mm , 250mm

2. Welding space: 330mm~1600mm

3. Thickness: 1.0mm , 1.2mm , 1.5mm , 1.8mm

4. Appearance: smooth / textured

1.Cell depth: 50mm , 100mm , 150mm , 200mm , 250mm

2. Welding space: 330mm~1600mm

3. Thickness: 1.0mm , 1.2mm , 1.5mm , 1.8mm

4. Appearance: smooth / textured

3.HDPE Paving Plastic Gravel Stabilizer Geocell Features:

1) Light material , resistant to wear , stable in chemical properties , anti-aging , resistant to acids and alkalis, applicable to different soil and desert and other geological conditions .

2)High limit on lateral direction , anti-skidding , anti-deformation , effectively enhance the supporting ability and scattered load function of roadbed .

3)High carrying capacity and good dynamic performance and high erosion ability .

4)The geometry size can be changed to meet different needs of the project , such as height and welding distance .

5)Retractable and small loading volume , convenient joint , speed construction .

6)Local material can be used during construction , reduce the construction cost , easy to be transported after folding together .

1) Light material , resistant to wear , stable in chemical properties , anti-aging , resistant to acids and alkalis, applicable to different soil and desert and other geological conditions .

2)High limit on lateral direction , anti-skidding , anti-deformation , effectively enhance the supporting ability and scattered load function of roadbed .

3)High carrying capacity and good dynamic performance and high erosion ability .

4)The geometry size can be changed to meet different needs of the project , such as height and welding distance .

5)Retractable and small loading volume , convenient joint , speed construction .

6)Local material can be used during construction , reduce the construction cost , easy to be transported after folding together .

4.Technical Parameters:

|

Material Properties

|

unit

|

|

|

|

|

Tested Method

|

||

|

Cell Depth

|

mm

|

75

|

100

|

150

|

200

|

|

||

|

Polymer Density

|

g/cm3

|

0.935-0.965

|

ASTM D 1505

|

|||||

|

Enviroment Stress Crack Resistance

|

Hours

|

>400

|

ASTM D 5397

|

|||||

|

Enviroment Stress Crack Resistance

|

Hours

|

6000

|

ASTM D 1693

|

|||||

|

Carbon Black Content

|

%

|

1.5%-2.0%

|

ASTM D 1603

|

|||||

|

Nominal Sheet Thickness Before Texturing

|

mm

|

1.27-5%,+10%

|

ASTM D 5199

|

|||||

|

Nominal Sheet Thickness After Texturing

|

mm

|

1.27-5%,+10%

|

ASTM D 5199

|

|||||

|

Strip Puncture Resistance

|

N

|

450

|

ASTM D 4833

|

|||||

|

Seam Peel Strength

|

N

|

1065

|

1420

|

2130

|

2840

|

EN ISO 13426-1B

|

||

|

Seam Efficiency

|

%

|

GRI100

|

GRI-GS13

|

|||||

|

Norminal Expanded Cell Size(width x length)

|

mm

|

320x287,475x508 etc

|

|

|||||

|

Norminal Expanded Panel Size(width x length)

|

m

|

2.56x8.35,4.5x5.0,6.5x4.5,6.1x2.44

|

|

|||||

5.HDPE paving plastic gravel stabilizer geocell Production &Packing:.

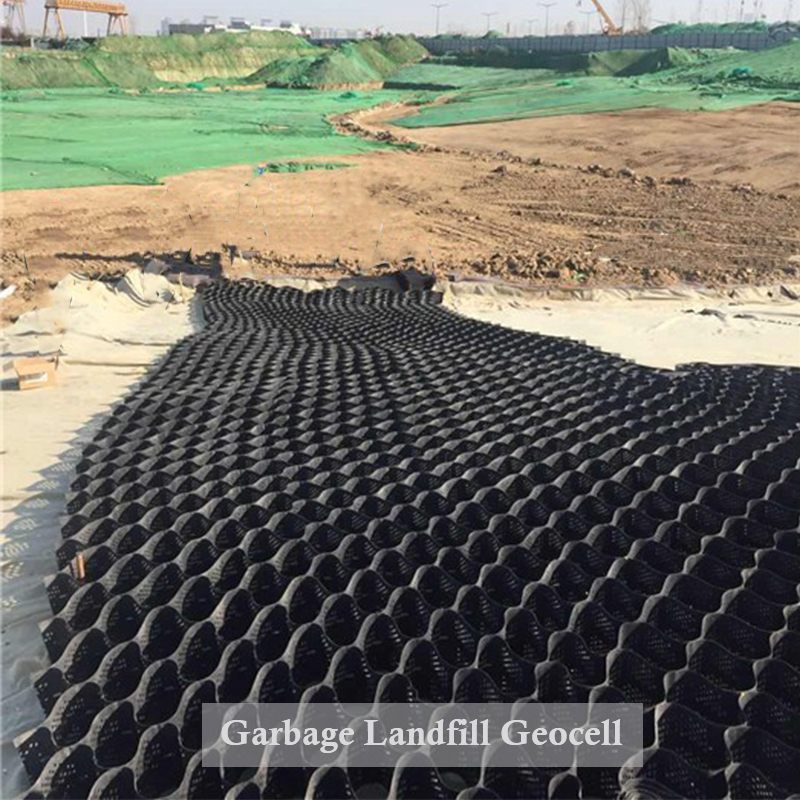

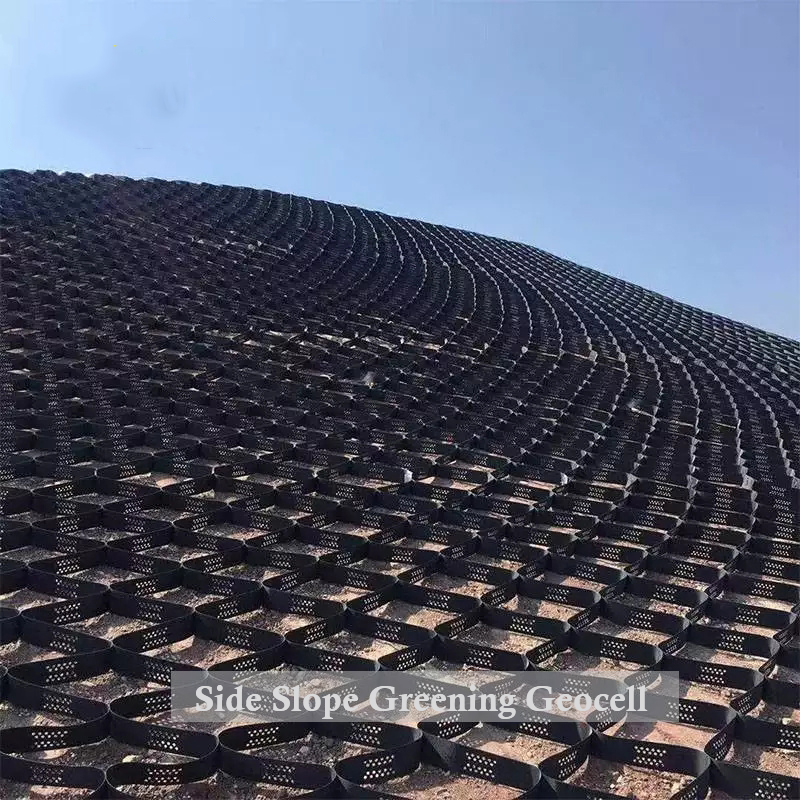

6.Applications:HDPE paving plastic gravel stabilizer geocell

1. Used for all kinds of road building , driveways , soil stabilization and embankment stabilization

2. Used to stabilize river embankments .

3. Used to prevent landslides .

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed , construction speed ,

good performance and greatly reduce the project cost .

1. Used for all kinds of road building , driveways , soil stabilization and embankment stabilization

2. Used to stabilize river embankments .

3. Used to prevent landslides .

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed , construction speed ,

good performance and greatly reduce the project cost .

7.HDPE Paving Plastic Gravel Stabilizer Geocell Production: